What is tergal fabric? Review of Tergal fabric

What is tergal fabric? Tergal fabric is woven from a combination of viscose and filament yarns. Viscose polyester yarn is spun by spinning mills. Polyester is a type of polymer that has ester groups. Polyester is a synthetic material obtained from petroleum derivatives.

Tergal fabric: viscose and filament polyester yarn

Viscose : It is a kind of natural fibers that is obtained from pine tree gum. Its technology is not in the hands of Iran and reaches consumers in Iran in the form of imports from other countries. The filament is obtained by spinning. Filament is a derivative of oil.

Viscose polyester yarn | Mahnam Textile Industries

Filament | Mahnam Textile Industries

Purchase simple tergal By combining fibers Polyester yarn viscose It can be seen that in recent years, due to the high price of viscose in the Iranian textile market, the percentages of polyester in this fabric have increased, which reduces the quality of tergal and tergal kajrah fabrics.

These yarns are available in the market today with percentages of 70 polyester 30 viscose or 65 polyester 35 viscose, 80 polyester 20 viscose, 90 polyester 10 viscose.

What is the difference between plain tragacanth and tragacanth fabric?

These yarns are twisted in machines and placed in weaving lines, and by adding filament between the polyester yarns, a raw tragacanth fabric is produced. Now, if the number of polyester yarns increases and the shape of the fabric becomes crooked, it is called crooked fabric. The average weight of Tergal fabric is 240 grams and the weight of Kajrah fabric is 285 grams. Today different weights of Plain and plain tragal fabrics It is available in the market that the consumer should pay attention to.

Introducing simple and kajrah tergal fabric finishing methods

After the production of raw tragacanth fabrics, these fabrics will be sent to dyeing factories for completion. Raw tragacanth fabric is completed in two ways in dyeing factories:

1- با دستگاه Jet under pressure

2- با دستگاه Thermosol

Completion process by jet jet method

The raw tergal fabric is poured into a device called a jet, which is like a very large pot, and then the desired color is added to it, and it is completed at high temperature.

Completion process by thermosol method

In the process Thermosol In this system, the paint is rubbed on the surface of the fabric in the form of a trowel, and this dyeing process is like painting a wall.

Join us to explore a variety of qualities Purchase simple tergal .

Problems and possible defects of Tergal fabric

1- یکنواخت نبودن رنگ پارچه ترگل

2- براق بودن رنگ پارچه ترگال

3- گوله گوله شدن ( تل شدن سطح پارچه )

4- گسستگی سطح پارچه ( بازشدگی سطح پارچه )

Non-uniform color of tergal fabric

This problem occurs in the process of finishing tergal fabric in dyeing. The reasons for this phenomenon are the extent of dyeing and lack of expertise, low technology in these factories.

Glossy fabric color

The color quality of the fabric is one of the important components in the finishing process, considering that the colors available in the market are sold at different prices. In each kilogram of color affects the type of color.

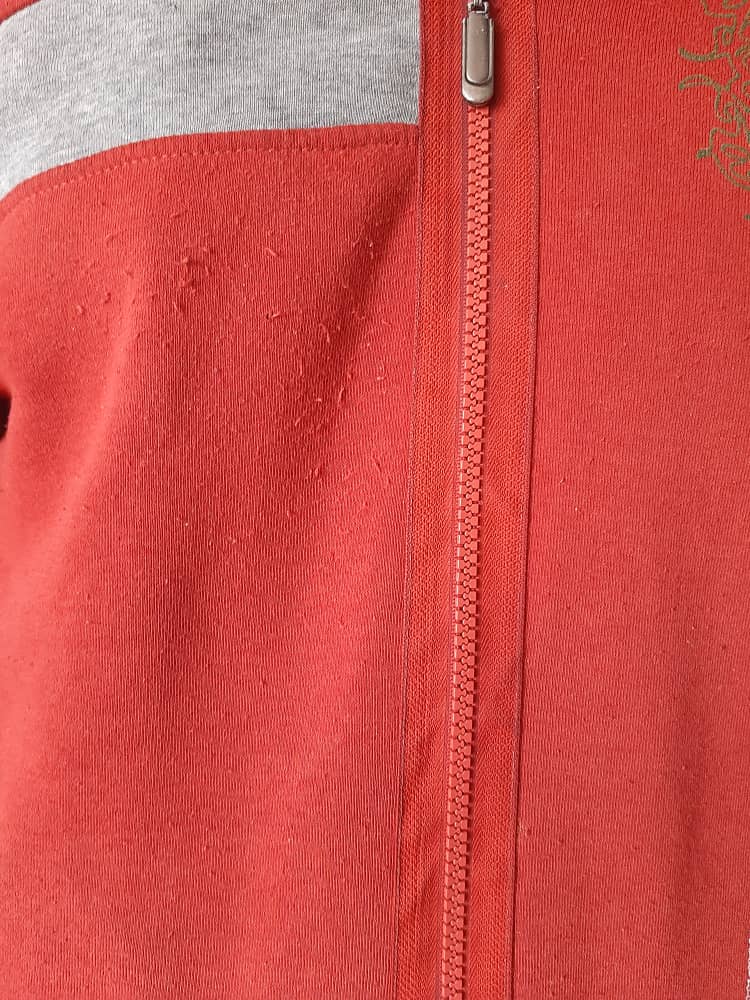

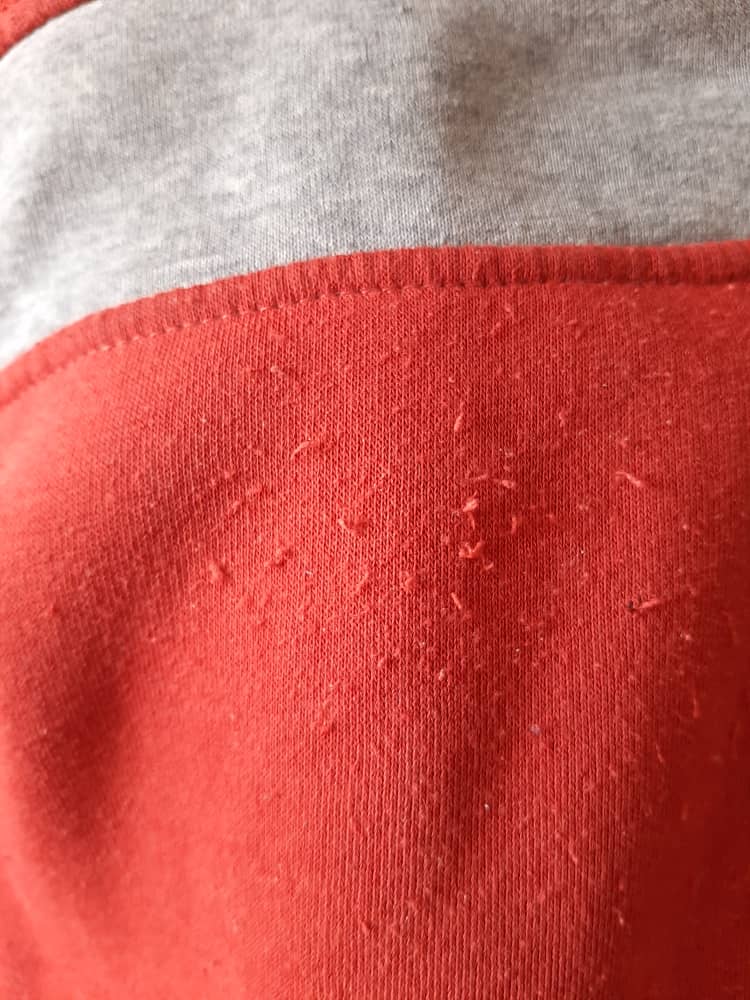

Clumping of the fabric surface (clumping of the fabric surface)

One of the most important disadvantages and many problems that manufacturers face is the bulging of the surface of tragal fabrics. This phenomenon can have different reasons, which depend on the purchase of quality yarn, but the main reasons are:

1- کم بودن تاب نخ به کار رفته شده در پارچه که بهترین میزان تاب نخ بین ۶۲۰ الی ۶۵۰ می باشد، که در دستگاه تابندگی با تابیده شدن در هم ضخیم تر می شود و مصرف می شود.

2- دومین دلیل کوتاه بودن الیاف پلی استر در نخ پلی استر ویسکوز که این هم یکی از مواردی هست که میتواند سبب تل شدن پارچه شود.

3- Filament yarn Used in Tergal fabric, which has a lower quality than the standard, of course, it is natural due to abrasion on the fabric.

4- Cracking of Tergal fabric, due to the increase in fabric production costs, some manufacturers lose the necessary rupture relative to each other by reducing the weight of the warp fabric and so-called reducing their knowledge.

Clumping of the fabric surface (clumping of the fabric surface)

Clumping of the fabric surface (clumping of the fabric surface)

How to test purchased fabrics before we get into trouble.

Tergal fabric color uniformity test

for review Tergal fabric color uniformity Place some tergal fabric in direct light and check the color veins in it or rub the fabric on top of each other and press it in the form of paper curling and then open it and the amount of color veins We compare it to high quality fabrics. You can also make sure that the color is stabilized by rubbing a damp white cloth on the fabric.

Clumping of the fabric surface test (clumping of the fabric surface)

For Clumping of the fabric surface test (clumping of the fabric surface) We wash and dry a piece of tergal fabric many times. It is better if we use a washing machine. After 5 steps of washing the fibers, if there is any, we will fluff ourselves.

Testing and checking the gloss of Tergal fabric surface

When this problem occurs in Tergal fabric, the percentage of viscose polyester yarn of the fabric should be checked. The lower the consumption of the fabric, the less viscose polyester yarn is used, the so-called sparkle of the fabric, which can be requested from the manufacturer of Targal fabric for the analysis of viscose polyester yarn.

Testing and checking the cracking of tregal fabric

You can for test and Checking the cracking of tregal fabric Weigh one meter of tergal fabric and if the weight of tergal fabric is low, find out that it is of poor quality.

Tergal fabric with a standard weight of 240 grams does not fall apart in any way.

Mahnam Textile Industries By using the latest laboratory equipment in order to provide the highest quality Torgal fabric and its standardization, it tries to provide the best and most quality fabric to our dear compatriots all over Iran.

You can by entering the page Wholesale fabric purchase Access all products of Mahnam Textile Industries. Contact us to buy tergal fabric in bulk.